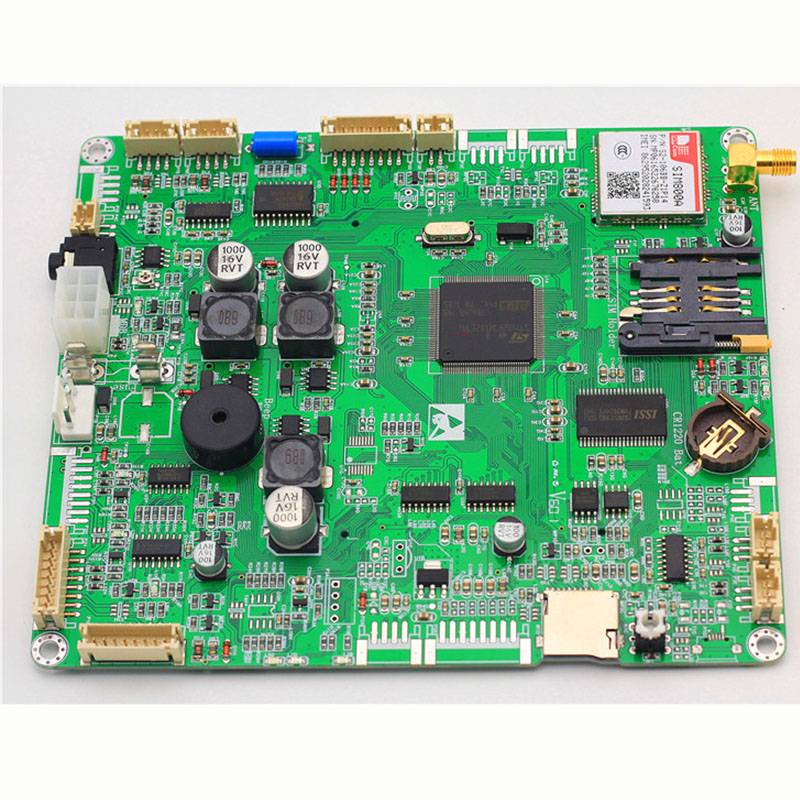

PCBA

Masiqonde inkqubo yokwenziwa kombane yePCBA ngokweenkcukacha:

● Ukwenziwa kweStencing yeSolder

Okokuqala nokuphambili, iInkampani yePCBAusebenzisa i-solder paste kwibhodi yesekethe eprintiweyo.Kule nkqubo, kufuneka ubeke i-solder paste kwiindawo ezithile zebhodi.Le nxalenye ineenxalenye ezahlukeneyo.

I-solder paste iyinhlanganisela yeebhola zetsimbi ezincinci ezahlukeneyo.Kwaye, eyona nto isetyenziswa kakhulu kwi-solder paste yi-tin ie 96.5%.Ezinye izinto ze-solder paste ziyisilivere kunye nobhedu kunye ne-3% kunye ne-0.5% yobuninzi ngokulandelelanayo.

Umenzi uxuba intlama kunye ne-flux.Ngenxa yokuba i-flux yikhemikhali enceda i-solder ekunyibilikeni nasekudibaniseni kwindawo yebhodi.Kufuneka ufake i-solder paste kwiindawo ezichanekileyo kunye nezixa ezifanelekileyo.Umenzi usebenzisa abafakeli abahlukeneyo ekusasazeni intlama kwiindawo ezijoliswe kuzo.

●Khetha Nendawo

Emva kokugqitywa ngempumelelo kwenyathelo lokuqala, umatshini wokukhetha kunye nendawo kufuneka enze umsebenzi olandelayo.Kule nkqubo, abavelisi babeka amacandelo ahlukeneyo e-elektroniki kunye nee-SMD kwibhodi yesekethe.Kule mihla, ii-SMDs zinoxanduva lwezinto ezingadibanisiyo zeebhodi.Uya kufunda indlela yokuthengisa ezi SMD ebhodini kumanyathelo azayo.

Unokusebenzisa iindlela zemveli okanye ezizenzekelayo ukukhetha kunye nokubeka izinto ze-elektroniki kwiibhodi.Ngendlela yendabuko, abavelisi basebenzisa i-tweezers ukubeka amacandelo ebhodini.Ngokuchasene noku, oomatshini babeka amacandelo kwindawo efanelekileyo kwindlela ezenzekelayo.

● Ukuthengiswa kwakhona

Emva kokubeka amacandelo kwindawo yawo efanelekileyo, abavelisi baqinisa i-solder paste.Bangawufeza lo msebenzi ngenkqubo “yokuphinda-phinda”.Kule nkqubo, iqela lokuvelisa lithumela iibhodi kwibhanti yokuhambisa.

iqela lemveliso lithumela iibhodi kwibhanti yokuhambisa.

Ibhanti yokuhambisa kufuneka idlule kwi-oven enkulu yokubuyisela kwakhona.Kwaye, i-oven yokubuyisela iphantse ifane ne-oven ye-pizza.I-oven iqulethe iiheater ezimbalwa ezinamaqondo obushushu ahlukeneyo.Emva koko, ii-heathers zifudumeza iibhodi kumaqondo obushushu ahlukeneyo ukuya kwi-250℃-270℃.Lo bushushu buguqula i-solder ibe yintlama ye-solder.

Ngokufanayo nezifudumezi, ibhanti lokuhambisa ngoko lidlula kuthotho lwezipholileyo.Izipholileyo ziqinisa intlama ngendlela elawulwayo.Emva kwale nkqubo, onke amacandelo e-elektroniki ahlala ebhodini ngokuqinileyo.

●Uhlolo noLawulo loMgangatho

Ngexesha lenkqubo yokubuyisela kwakhona, ezinye iibhodi mhlawumbi ziza noqhagamshelwano olubi okanye zibe zifutshane.Ngamagama alula, kusenokubakho iingxaki zoqhagamshelwano ngexesha lenyathelo langaphambili.

Ngoko kukho iindlela ezahlukeneyo zokujonga ibhodi yesekethe malunga nokungahambi kakuhle kunye neempazamo.Nazi ezinye iindlela eziphawulekayo zovavanyo:

● Ukujonga ngesandla

Nakwixesha lokwenziwa kunye novavanyo oluzenzekelayo, ukujonga ngesandla kusenokubaluleka okubalulekileyo.Nangona kunjalo, ukujonga ngesandla kusebenza kakhulu kwiPCB PCBA encinci.Ke ngoko, le ndlela yokuhlola ayichanekanga kwaye ayisebenzi kwibhodi yesekethe yePCBA.

Ngaphandle koko, ukujonga amacandelo omgodi ixesha elide kuyacaphukisa kunye nokukhathala okubonakalayo.Ngoko kunokukhokelela ekuhlolweni okungachanekanga.

● Ukuhlolwa okuzenzekelayo okuSebenzayo

Kwibhetshi enkulu ye-PCB PCBA, le ndlela yenye yezona ndlela zintle zokuvavanya.Ngale ndlela, umatshini we-AOI uhlola ii-PCB usebenzisa iikhamera ezininzi ezinamandla amakhulu.

Ezi khamera zigubungela zonke ii-engile ukuze zihlole ukudityaniswa kwee-solder ezahlukeneyo.Oomatshini be-AOI bayawaqaphela amandla oqhagamshelo ngokukhanya okukhanyayo okuvela kuqhagamshelo lwe-solder.Oomatshini be-AOI banokuvavanya amakhulu eebhodi kwiiyure ezimbalwa.

● Ukuhlolwa kwe-X-Ray

Yenye indlela yovavanyo lwebhodi.Le ndlela ayiqhelekanga kodwa isebenza ngakumbi kwiibhodi zeesekethe eziyinkimbinkimbi okanye ezinomaleko.I-X-reyi inceda abavelisi ukuba bahlole iingxaki zomgangatho ophantsi.

Ngokusebenzisa ezi ndlela zikhankanywe ngasentla, ukuba kukho ingxaki, iqela labavelisi lisenokuyithumela loo nto ukuze iphinde isebenze okanye ichithwe.

Ukuba uhlolo alufumani mpazamo, inyathelo elilandelayo kukukhangela ukusebenza kwalo.Kuthetha ukuba abavavanyi baya kukhangela ukuba ngaba ukusebenza kwayo kuhambelana neemfuno okanye hayi.Ngoko ke ibhodi inokufuna ulungelelwaniso ukuvavanya ukusebenza kwayo.

●Ukufakwa kweCandelo lokutyhutyha

Amacandelo e-elektroniki ayahluka ukusuka ebhodini ukuya ebhodini kuxhomekeke kuhlobo PCBA.Umzekelo, iibhodi zinokuba neentlobo ezahlukeneyo zamacandelo e-PTH.

I-Plated ngokusebenzisa imingxuma yintlobo ezahlukeneyo zomngxuma kwiibhodi zesekethe.Ngokusebenzisa le mingxuma, amacandelo kwiibhodi zeesekethe adlulisa umqondiso kunye nokusuka kwiileyile ezahlukeneyo.Amacandelo e-PTH afuna iintlobo ezikhethekileyo zeendlela zokuthambisa endaweni yokusebenzisa intlama kuphela.

● Ukusoda ngezandla

Le nkqubo ilula kakhulu kwaye iqonde.Kwisikhululo esinye, umntu omnye angafaka lula icandelo elinye kwi-PTH efanelekileyo.Emva koko, umntu uya kudlula loo bhodi kwisikhululo esilandelayo.Kuya kubakho izikhululo ezininzi.Kwisikhululo ngasinye, umntu uya kufaka icandelo elitsha.

Umjikelo uyaqhubeka de kufakwe onke amacandelo.Ke le nkqubo ingaba yinde exhomekeke kwinani lamacandelo e-PTH.

● Ukubethelwa kwamaza

Yindlela ezenzekelayo yokuthengisa.Nangona kunjalo, inkqubo ye-soldering ihluke ngokupheleleyo kule ndlela.Kule ndlela, iibhodi zidlula kwi-oven emva kokubeka ibhanti lokuhambisa.I-oven iqulethe i-solder etyhidiweyo.Kwaye, i-solder etyhidiweyo ihlamba ibhodi yesiphaluka.Nangona kunjalo, olu hlobo lwe-soldering alunakwenzeka kwiibhodi zeesekethe eziphindwe kabini.

● Uvavanyo kunye noHlolo lokugqibela

Emva kokugqitywa kwenkqubo ye-soldering, ii-PCBA zidlula ukuhlolwa kokugqibela.Kulo naliphi na inqanaba, abavelisi banokudlula iibhodi zeesekethe ukusuka kumanyathelo angaphambili okufakwa kweendawo ezongezelelweyo.

Uvavanyo olusebenzayo lelona gama liqhelekileyo lisetyenziselwa uhlolo lokugqibela.Kweli nyathelo, abavavanyi babeka iibhodi zeesekethe ngesantya sabo.Ngaphandle koko, abavavanyi bavavanya iibhodi phantsi kweemeko ezifanayo apho isiphaluka siya kusebenza khona.

Ixesha lokuposa: Jul-14-2020